ROLL LOAD CELL

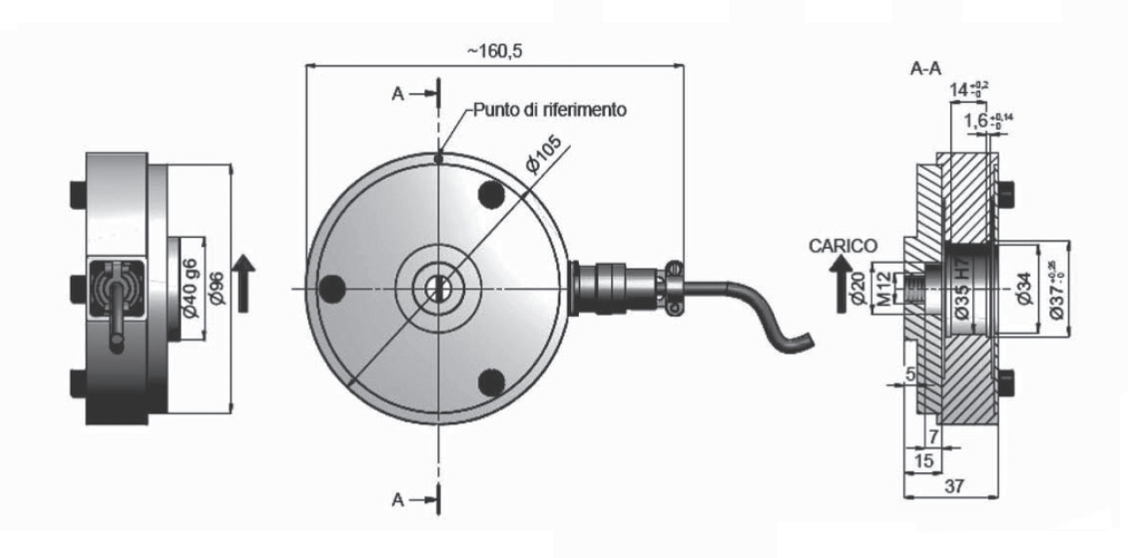

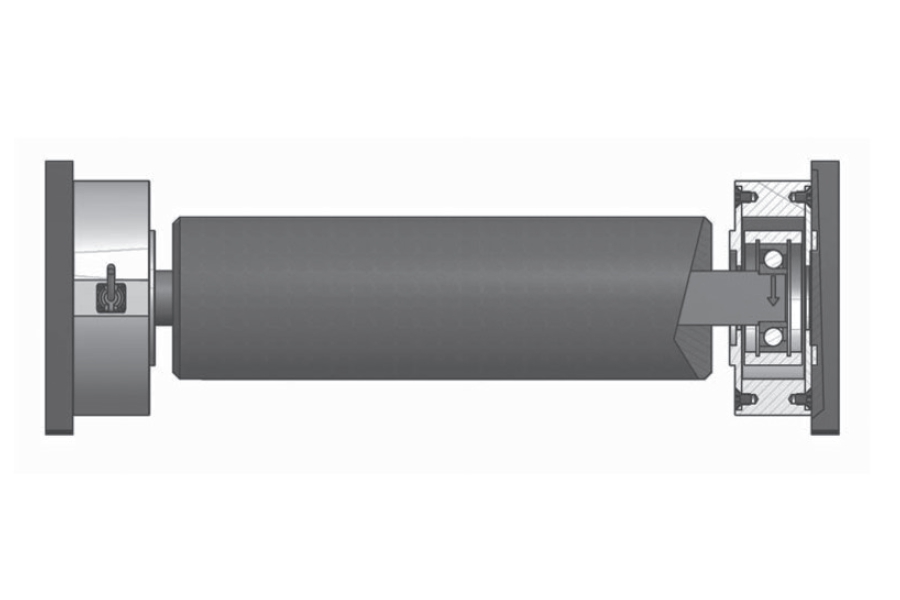

Features: Possibility to rotate the cell 360 °. Low thickness. For bearings external diam. 28, 32, 35, 40, 42 mm, for new and existing machines.

Applications: for the measure of tension tape, tessil, paper, metal laminated, plastic, rubber, flexographic printing presses and for photografic development machinery, etc.

![]() Click to enlarge image

Click to enlarge image

| Material | Stainless steel/Aluminium |

| Nominal load | 150, 250, 350, 500, 750, 1000 N |

| Limit load | 500 % of full scale |

| Breaking load | 2000 % of full scale |

| Nominal load deflection | 0,10 mm |

| Supply voltage | Maximum 18 V dc |

| Sensitivity | 1 mV/V |

| Output tollerance | 0,1 % F.S. |

| Zero tollerance | 1 % F.S. |

| Linearity | 0,1 % F.S. |

| Hysteresis | 0,03 % F.S. |

| Reapeatability | 0,1 % F.S. |

| Input resistance | 350-360 ohm |

| Output resistance | 350-353 ohm |

| Insulation resistance | >= 2000 Mohm |

| Creep (30 Minutes) | 0,03 % F.S. |

| Thermal compensation | -10 / +40°C (14 / +104°F) |

| Operating temperature | -20 / +70°C (-4 / +158°F) |

| Temperature deviation zero | 0,003 % F.S. / °C |

| Temperature deviation full scale | 0,002 % F.S. / °C |

| Protection class | IP 54 / IP 65 |

| Connection | Panel male connector UTS08E4P |

| Standard cable length | Loose female connector UTS6JC8E4S, connection cable 4 x 0,25 (length to be defined) |

| Type | CONNECTOR M12 RSFM5 MALE |

| Length | 5 m (body lead cell not connected shield) |

| Pin 4 | - IN |

| Pin 2 | - OUT |

| Pin 3 | + IN |

| Pin 1 | + OUT |

General precautions to be followed in the installation and assembly of load cells: